Testing

AT CHHATARIYA RUBBER & CHEMICAL INDUSTREIS we strive to provide to Maintain the Highest Quality of Products

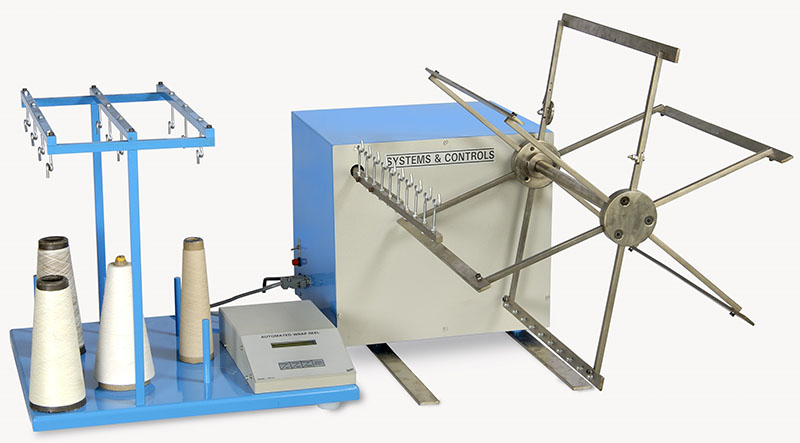

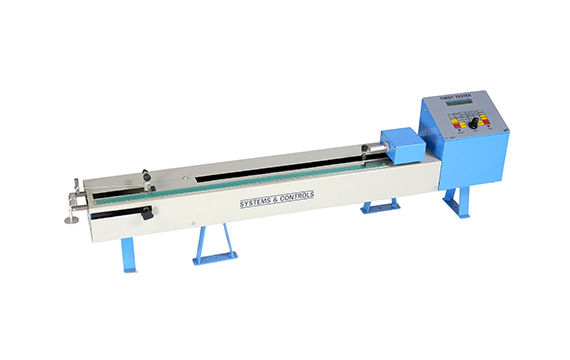

LABORATORY: TWIST TESTER MACHINE

Twist Tester is a machine used to get the level of twist in single or multi-plied yarn. The instrument is used on single, double, plied, and multi-filament yarn.

AGING & HUMIDITY CONTROLLED OVEN

Oven for testing final product and raw material of hose, conditioning of hose moisture content, volatile matter etc.

ABRASION TEST

Tests Conducted under IS and BS Specifications to ensure the workmanship of the Hose under Rugged Conditions.

HEAT RESISTANCE TEST

To ensure the workmanship of the hose in High Temperature Zones during fire fighting.

PRESSURE TEST

The most important test for the hoses to ensure it's ratings and recommended work conditions is the Pressure Test.

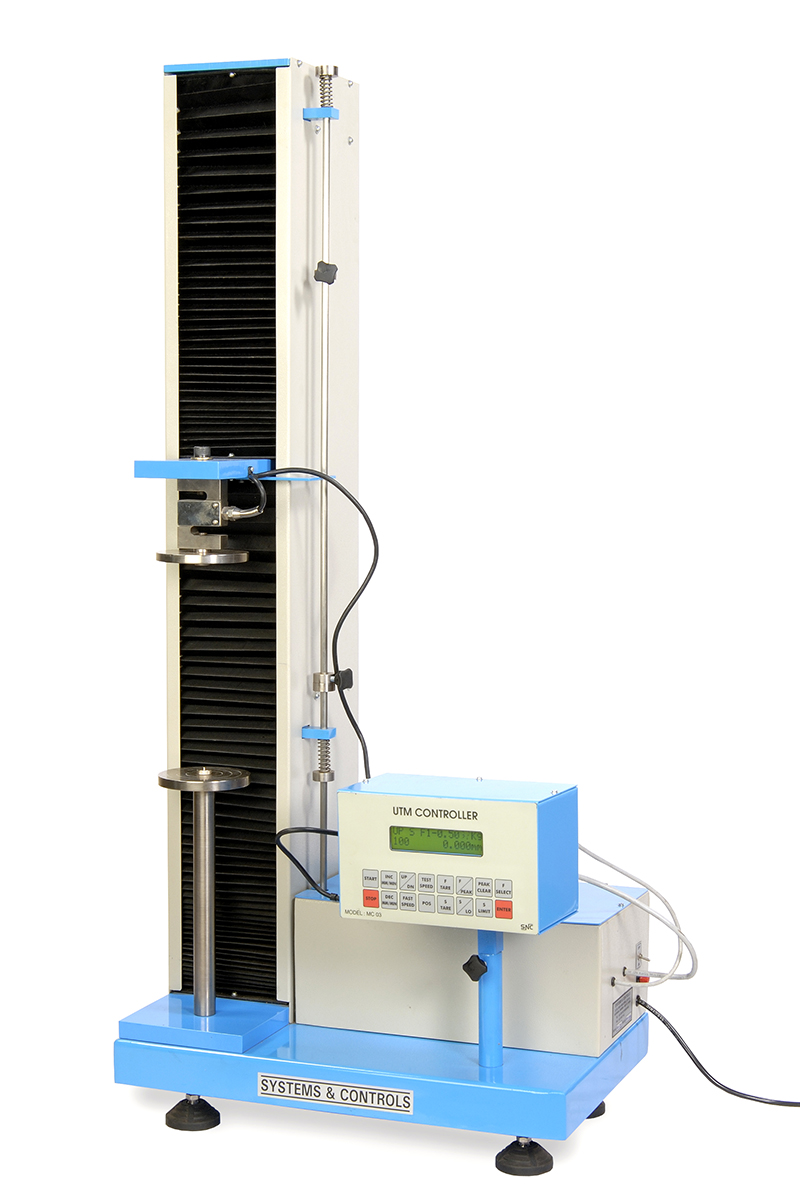

TENSILE TEST

To ensure the reliability and durability of the innerlining of the hose during storage and use the Tensile Test is used.

HOT AIR AGEING

Hot Air Oven for testing final product and Rubber properties @ elevated temperatures.